The Evolution of Polymer Materials

Engineering polymers have long been at the forefront of material science, revolutionizing industries from healthcare to aerospace. These synthetic materials, characterized by their exceptional mechanical properties, thermal stability, and chemical resistance, have paved the way for countless innovations. As we navigate the 21st century, the landscape of engineering polymers is undergoing a transformative shift, driven by rapid advancements in polymer science and an increasing focus on sustainability.

High-Performance Polymers: Pushing the Boundaries of Material Engineering

At the vanguard of this evolution are high-performance polymers, designed to meet the rigorous demands of advanced engineering applications. Polyether ether ketone (PEEK), known for its exceptional mechanical strength and thermal stability, and polyimides (PI), recognized for their thermal endurance and chemical resistance, are prime examples. These materials excel in sectors ranging from aerospace and automotive to electronics and medical devices, where reliable performance under extreme conditions is paramount.

The synthesis and processing of high-performance polymers require specialized techniques to maintain their exceptional properties while enabling complex shapes and structures. Innovations in injection molding, extrusion, and additive manufacturing have been instrumental in realizing the full potential of these materials, expanding their applications and contributing to more efficient and sustainable manufacturing practices.

Bio-based and Biodegradable Polymers: Towards a Sustainable Future

In response to growing environmental concerns, the development of bio-based and biodegradable polymers has gained significant momentum. These materials, derived from renewable resources and designed to decompose through natural processes, offer a sustainable alternative to traditional petroleum-based plastics. Polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) are notable examples, showcasing comparable, if not superior, properties to their fossil fuel-based counterparts.

The production of bio-based polymers often involves more environmentally friendly processes, such as microbial fermentation, contributing to a reduced carbon footprint. Biodegradable polymers, on the other hand, provide a closed-loop solution, addressing the pressing issue of plastic waste accumulation by breaking down into natural substances through the action of microorganisms.

Despite their promise, bio-based and biodegradable polymers face challenges in terms of cost-effectiveness, performance limitations, and the need for better waste management infrastructure to ensure effective decomposition. Ongoing research and development efforts, however, are continuously working to address these barriers and expand the applications of these sustainable materials.

Intelligent and Functional Polymers: Adaptive and Responsive Materials

The latest frontier in polymer engineering is the realm of intelligent and functional polymers. These materials can respond to external stimuli, such as temperature, pH, or light, in a controlled and reversible manner, opening up new possibilities for innovative applications. Self-healing polymers, shape-memory polymers, and responsive polymers are at the forefront of this technological revolution.

Self-healing polymers can automatically repair damage without external intervention, mimicking the self-repairing mechanisms found in biological systems. Shape-memory polymers, on the other hand, can return from a deformed state to their original shape upon exposure to a specific stimulus, enabling applications in medical devices, aerospace, and robotics. Responsive polymers that alter their physical or chemical properties in response to environmental conditions find uses in drug delivery systems and intelligent textiles.

The integration of intelligent and functional polymers with emerging technologies, such as nanotechnology and advanced manufacturing, further enhances their potential, leading to materials with unprecedented capabilities. As research in this field continues, the future promises even more innovative and adaptable polymer-based solutions across a wide range of industries.

Advanced Manufacturing Techniques: Shaping the Future of Polymer Engineering

Technological innovations in polymer engineering have ushered in a new era of material design and application, significantly expanding the potential of polymers beyond traditional boundaries. Advanced manufacturing techniques, such as 3D printing, electrospinning, and nano-fabrication, have revolutionized how polymer products are conceived and produced, creating complex geometries and structures previously unattainable.

3D Printing: Democratizing Polymer Manufacturing

3D printing, or additive manufacturing, has emerged as a cornerstone of modern polymer engineering, enabling the direct fabrication of complex parts and structures from digital models. This technique offers unparalleled customization and design flexibility, allowing for the use of a wide range of polymers, from commodity plastics to high-performance materials like PEEK and PEI. The ability to produce bespoke components rapidly and efficiently has significant implications for prototyping, product development, and small-scale production, reducing time-to-market and enabling more agile manufacturing practices.

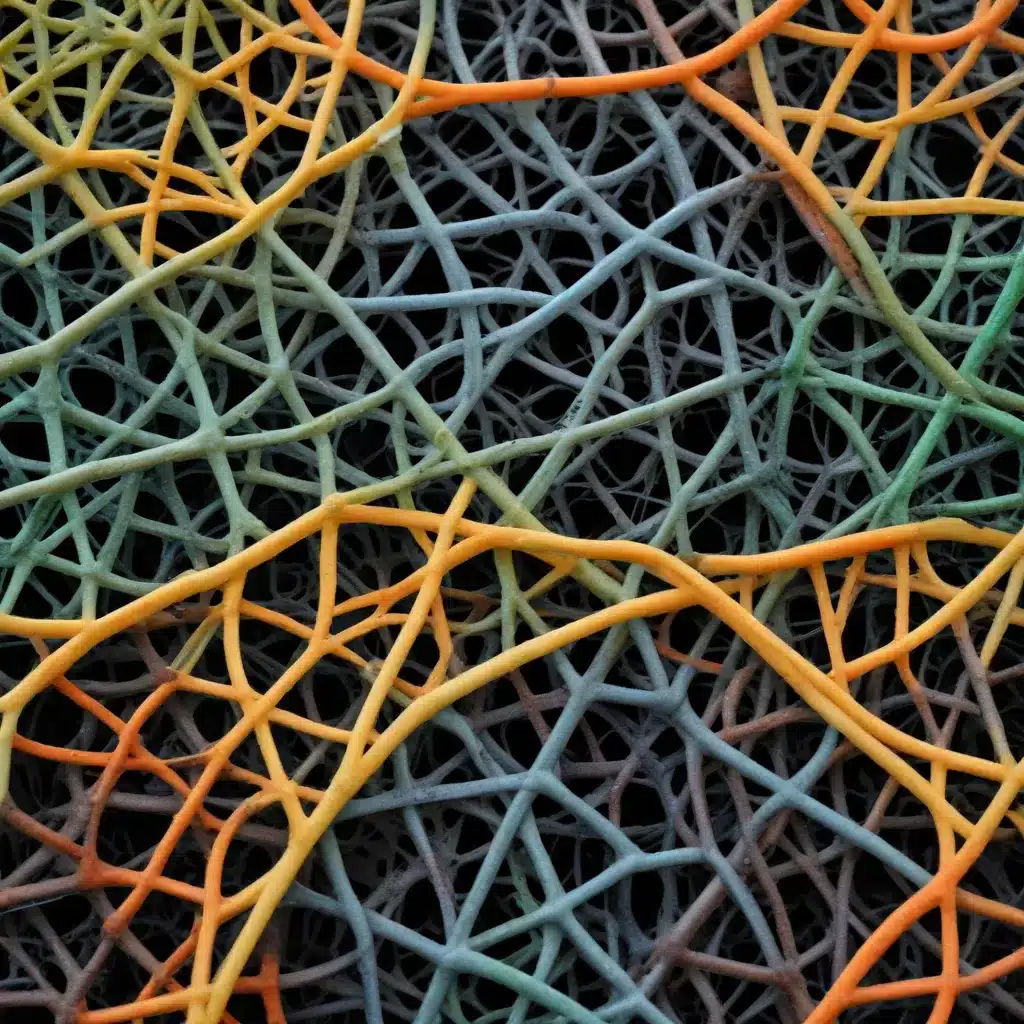

Electrospinning: Producing Polymer Nanofibers

Electrospinning is another innovative technique that has been instrumental in the development of advanced polymer materials. By applying a high voltage to a polymer solution or melt, this process creates ultrafine fibers with diameters ranging from a few nanometers to micrometers. The resulting non-woven fabrics exhibit enhanced properties, such as increased tensile strength and improved barrier performance, making them ideal for various applications, including filtration, tissue engineering, and wearable sensors.

Nano-fabrication: Manipulating Polymers at the Molecular Scale

Nano-fabrication techniques encompass a range of processes designed to manipulate materials at the nanoscale, enabling the development of polymer nanocomposites with tailored electrical, mechanical, and optical properties. By precisely arranging nanoparticles within a polymer matrix, these techniques unlock new possibilities for designing polymers with previously unattainable characteristics, opening up applications in electronics, energy, and healthcare.

The integration of these advanced manufacturing techniques in polymer engineering has profound implications for customization, scalability, and the intrinsic properties of polymer-based products. The democratization of manufacturing, the mass production of nano-engineered materials, and the introduction of new functionalities all contribute to the ongoing evolution of polymer applications across various industries.

Polymer Nanocomposites: Unlocking the Potential of Hybrid Materials

Polymer nanocomposites represent a groundbreaking class of materials that harness the unique properties of nanoparticles to significantly enhance the mechanical, thermal, and barrier properties of polymers. By embedding nanoparticles, ranging from nanoclays and metal oxides to carbon nanotubes and graphene, within a polymer matrix, these composites achieve performance characteristics that far exceed those of conventional polymers and composites.

The application of nanomaterials within polymer matrices has opened up new frontiers in material science, enabling the creation of materials with tailored physical, chemical, and biological properties. From structural-colored nanomaterials to organo-metallic nanomaterials and molecular machines, these innovative polymer nanocomposites are revolutionizing fields as diverse as electronics, healthcare, and environmental protection.

Despite the remarkable potential of polymer nanocomposites, their development and application face several significant challenges, particularly in terms of nanoparticle dispersion, polymer-nanoparticle compatibility, and environmental impact. Addressing these challenges is crucial for maximizing the benefits of these materials while minimizing any adverse effects.

Sustainability and Environmental Responsibility in Polymer Engineering

Sustainability and environmental considerations have become increasingly central to the development and application of polymer materials. As global awareness of the environmental impact of plastic waste grows, the need for efficient recycling processes and the adoption of circular economy principles has become more pronounced.

Polymer Recycling: Closing the Loop

Mechanical recycling and chemical recycling represent two primary approaches to addressing the challenges of polymer waste management. Mechanical recycling involves physically reprocessing plastic waste into new products, while chemical recycling breaks down polymers into their monomers or other essential chemical components, which can then be repolymerized.

Both methods present their own set of challenges, from the degradation of material properties in mechanical recycling to the complexity and cost-effectiveness of chemical recycling processes. Ongoing research and innovation, however, are continuously working to address these barriers, enhancing the efficiency and sustainability of polymer recycling.

The transition towards a circular economy for polymers extends beyond recycling, encompassing the design, production, and use of plastics in a way that minimizes waste and promotes resource efficiency. This approach requires collaboration across the entire value chain, from material suppliers to product designers, manufacturers, consumers, and waste managers, as well as supportive policies and incentives to facilitate the adoption of circular practices.

Regulatory Frameworks and Standards: Guiding Sustainable Polymer Development

The global landscape of polymer production, use, and disposal is increasingly influenced by a complex framework of regulations and standards aimed at promoting sustainability, safety, and environmental stewardship. Regulations like the European Union’s REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the U.S. Toxic Substances Control Act (TSCA) play a critical role in guiding the development and application of polymers, ensuring that they meet stringent environmental and safety requirements.

Alongside regulations, the development of standards for material specification, sustainability, and environmental impact assessment has been instrumental in driving the polymer industry towards more responsible and innovative practices. These standards help ensure the consistent evaluation of polymer properties and performance, as well as the adoption of sustainable production and disposal methods.

The integration of sustainability and environmental responsibility into the polymer industry is a complex and multifaceted challenge, but one that is essential for the long-term viability and acceptance of these materials. By addressing technical, economic, and regulatory barriers, the polymer industry can continue to develop innovative solutions that address global challenges while minimizing environmental impact.

Polymers in Energy and Electronics: Powering the Future

The application of polymers in the energy and electronics sectors has been transformative, revolutionizing how we generate, store, and utilize power, as well as enabling the development of advanced electronic devices.

Polymers in Energy Storage and Conversion

In the energy sector, polymers play a critical role in battery technology, serving as electrolytes and separators in energy storage systems. The evolution of polymer electrolytes has been a game-changer for the development of solid-state batteries, offering improved safety and potentially higher energy densities compared to traditional liquid electrolytes.

Polymers also find application in the fabrication of organic photovoltaic (OPV) cells, providing a lightweight, flexible, and cost-effective alternative to traditional silicon-based solar panels. The ability to manufacture OPV cells using roll-to-roll processing techniques has significantly reduced production costs and opened up new possibilities for integrating solar cells into various surfaces and materials.

Polymers in Electronics and Devices

The field of electronics has also witnessed significant advancements through the use of conductive and semiconductive polymers. These materials have enabled the development of flexible and wearable electronic devices, such as displays, sensors, and circuits that can be integrated into clothing or applied directly to the skin. Conductive polymers are being explored for use in transistors, light-emitting diodes (LEDs), and electrochromic displays, offering advantages in flexibility, processability, and the potential for novel device architectures.

Innovations in semiconductive polymers are also revolutionizing the semiconductor industry, as these materials can be tuned to exhibit desirable electronic properties. This has led to the fabrication of field-effect transistors (FETs), photodetectors, and other key components of electronic circuits using cost-effective printing techniques, rather than the expensive and complex processes required for traditional inorganic semiconductors.

The integration of polymers into energy and electronics applications continues to push the boundaries of what is possible, driving innovation and addressing global challenges in sustainability, efficiency, and performance.

Polymers in Healthcare and Biomedical Engineering: Advancing Medical Solutions

The healthcare and biomedical engineering sectors have also witnessed a transformative impact from the application of polymers. These versatile materials have revolutionized drug delivery systems, tissue engineering, and wearable medical devices, offering solutions to complex medical challenges.

Polymers in Drug Delivery Systems and Tissue Engineering

In drug delivery systems, polymers are used to encapsulate medications, providing controlled release and protecting the active ingredients until they reach the target site within the body. Biodegradable polymers, such as PLGA (polylactic-co-glycolic acid), are particularly valuable in this field due to their biocompatibility and ability to break down into natural byproducts over time.

Polymer scaffolds also play a crucial role in tissue engineering, mimicking the extracellular matrix and providing a structure upon which cells can adhere, grow, and form new tissue. The gradual dissolution of these biodegradable polymer scaffolds as the new tissue forms eliminates the need for surgical removal.

Polymers in Wearable Medical Devices

Polymers are essential in the development of wearable medical devices, including sensors and implants, due to their flexibility, durability, and compatibility with the human body. These materials enable the design of devices that can continuously monitor health parameters or provide therapeutic functions with minimal discomfort to the patient, while also meeting stringent biocompatibility, sterilization, and regulatory requirements.

The successful integration of polymers in healthcare and biomedical engineering has led to significant advancements in patient care, improving outcomes and opening new avenues for treatment and research. As the field continues to evolve, the interplay of polymer science, biomedical engineering, and regulatory compliance will be crucial in driving further innovations and ensuring the safe and effective application of these materials.

Polymers in Automotive and Aerospace: Enhancing Performance and Sustainability

The automotive and aerospace industries have also witnessed a transformative impact from the integration of engineering polymers. These advanced materials have played a pivotal role in improving fuel efficiency, safety, and design flexibility, contributing to more sustainable and innovative transportation solutions.

Polymers in the Automotive Sector

In the automotive sector, the shift towards lightweight materials, such as carbon fiber-reinforced plastics (CFRP) and polyamides (PA), has directly responded to the need for improved fuel efficiency and reduced emissions. By replacing traditional materials like steel and aluminum, these polymer-based composites offer significant weight reductions, leading to better fuel economy and lower greenhouse gas emissions.

Moreover, the enhanced strength and impact resistance of these polymers have improved vehicle safety, absorbing and distributing energy more effectively during collisions. The inherent flexibility of polymers has also enabled innovative aerodynamic designs, contributing to enhanced performance and improved passenger comfort.

Polymers in the Aerospace Industry

The aerospace industry presents even more stringent material requirements, where every kilogram saved can lead to substantial fuel savings over an aircraft’s lifetime. Engineering polymers, including PEEK and PPS, are extensively used in both structural components and interior applications, offering resistance to fatigue, corrosion, and thermal and acoustic insulation.

The design flexibility afforded by polymers has also allowed for the creation of complex shapes and structures, contributing to improved aerodynamics and performance. This flexibility has facilitated the integration of advanced functionalities, such as embedded sensors and electronics, further enhancing the capabilities and safety of aerospace vehicles.

The widespread adoption of engineering polymers in the automotive and aerospace sectors has not been without its challenges, including the need for specialized manufacturing processes and the management of material costs. However, ongoing research and development efforts continue to address these issues, driving innovation and paving the way for a more sustainable and efficient future in transportation.

Navigating the Challenges and Opportunities of Engineering Polymers

The journey of engineering polymers from the laboratory to widespread industrial application is fraught with technical and economic challenges that must be navigated to unlock their full potential. Scalability of production, cost-effectiveness, and ensuring performance consistency across large-scale manufacturing are just a few of the hurdles that the polymer industry must overcome.

Environmental and regulatory challenges also significantly impact the development, use, and disposal of engineering polymers. As global awareness of environmental issues grows, there is an increasing demand for sustainable materials and practices. Governments worldwide are implementing stricter regulations on waste management, recycling quotas, and the use of hazardous substances in polymer production, posing significant challenges for manufacturers in terms of compliance and adaptation.

Despite these challenges, the outlook on future innovations in material science and engineering, particularly within polymers, is optimistic. Potential breakthroughs are expected to arise from the ongoing exploration of novel polymer structures, the development of intelligent and responsive materials, and the enhancement of sustainable polymers derived from renewable resources.

Interdisciplinary research and global collaboration will be crucial in driving these advancements, bridging the gap between chemistry, physics, biology, and engineering to uncover new insights and applications for polymers. By addressing the complex, multifaceted challenges faced by the polymer industry, these innovations promise to revolutionize healthcare, energy, and a multitude of other sectors, shaping a more sustainable and technologically advanced future.

As the field of engineering polymers continues to evolve, stakeholders across the spectrum, from researchers and industry professionals to policymakers, must engage in sustained efforts to harness the potential of these materials. By doing so, the polymer industry can contribute to a future where material science plays a pivotal role in solving some of the most pressing challenges of our time, fostering a more sustainable, efficient, and technologically advanced society.